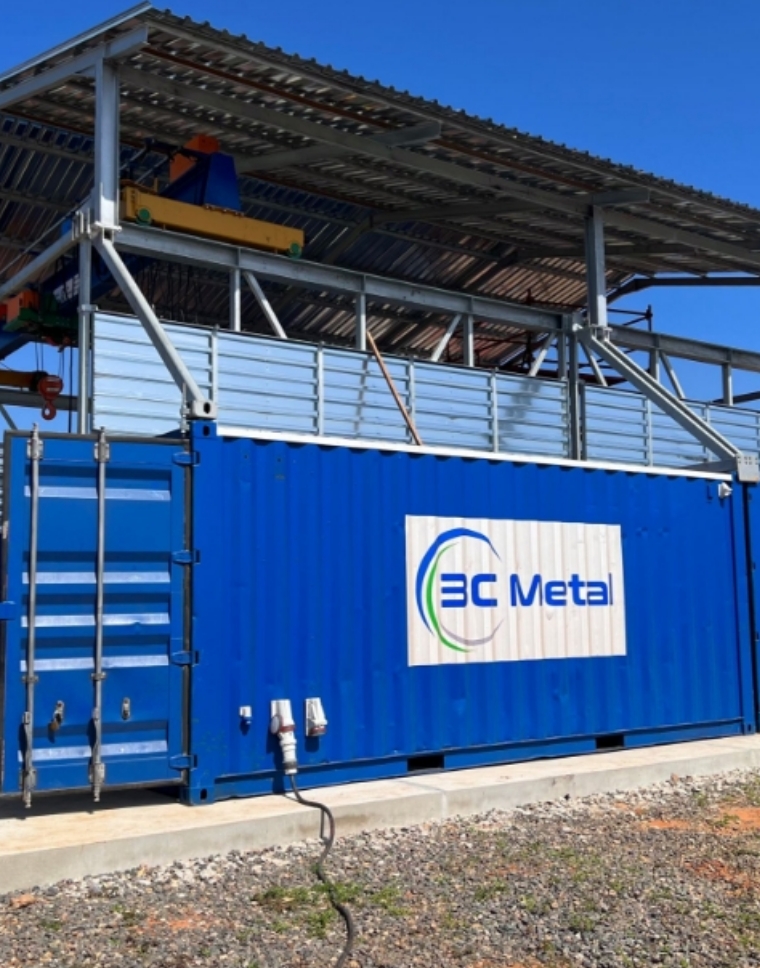

3C Metal Belmet’s Walvis Bay facility in Namibia offers heavy fabrication capabilities and a strategic base supporting operations across West Africa and multiple industrial sectors.

Established in 2008 as Belmet Marine Engineering Namibia, the facility became part of the 3C Metal Group through a 51% majority shareholding agreement with Belmet. In 2019, the shareholding increased to 75%, leading to its renaming as “3C Metal Belmet.”

Strategically located at the port of Walvis Bay, the facility serves a broad range of industries, including oil and gas, diamond mining, mineral processing, and marine. Its location and capabilities make it a key asset for regional operations, offering efficient access to offshore markets and delivering high-quality fabrication and engineering services.

Company Overview

- Location: Walvis Bay, Namibia

- Facility: 2 x pre-fabrication workshops (total area 2000m²), 1,500m² yard, 500m² paint facilities – blast booth, paint shed, recycle grid, electric air compressor.

- Specialized services: Fabrication and construction, laser scanning, engineering, project management, procurement, personnel deployment/supply, offshore- and onsite installation.

- Certifications: ISO 9001 | ISO 45001

Capabilities and Services

We deliver integrated fabrication, engineering, and installation services, offering customized solutions for complex projects in the oil, gas, and marine sectors.

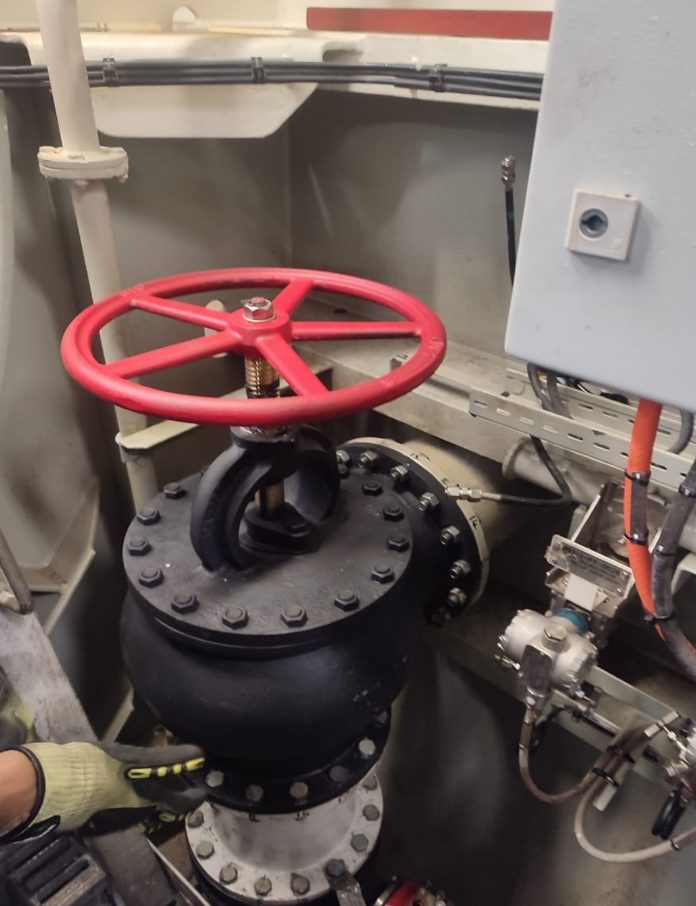

PRESSURE PIPING

High Pressure and Low Pressure piping systems for industrial fluid transport.

HYDRAULIC PIPING

Hydraulic piping systems for high-pressure fluid transmission in industrial, marine, and heavy machinery applications.

POST WELD HEAT TREATMENT (PWHT)

PWHT process reduces residual stresses and enhances material strength, durability, and structural integrity after welding.

HP TESTING

High-pressure testing services up to 30,000 PSI ensure system integrity, safety, and performance under extreme conditions.

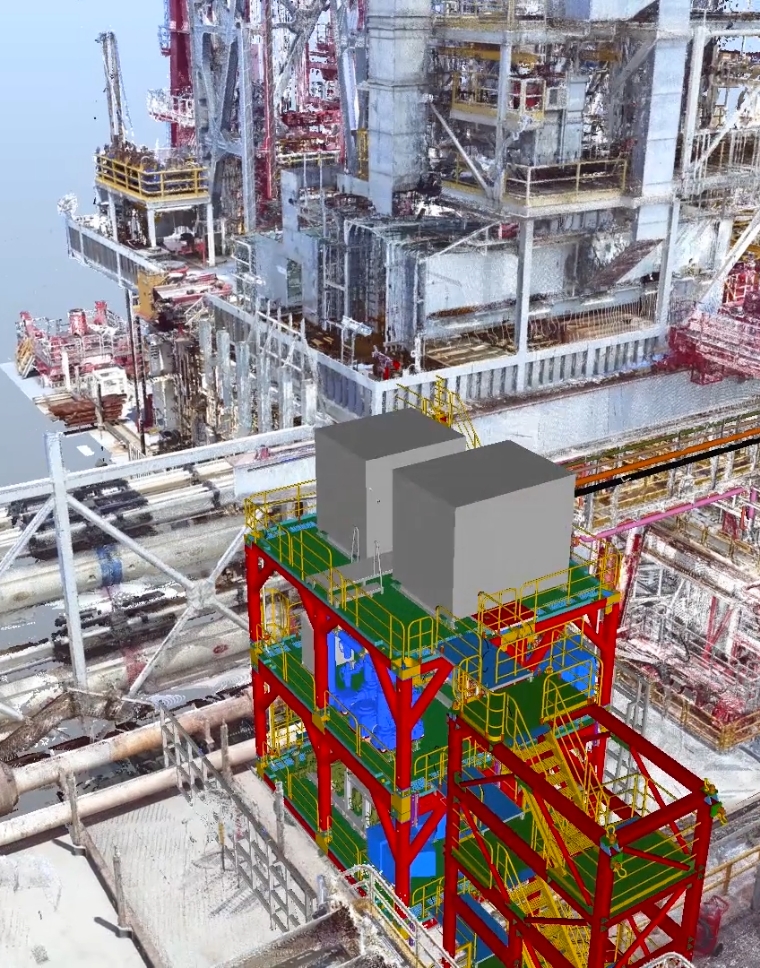

STRUCTURAL FABRICATION

Structural fabrication services for building durable steel frameworks in oil and gas, industrial, and infrastructure applications.

OUR PROJECTS

Explore our diverse portfolio of piping and structural projects, executed with precision through expert welding, NDT, pressure testing, heat and surface treatments, and completed with meticulous installation and inspection services.

OUR CERTIFICATIONS

Backed by globally accredited certifications, we consistently deliver services that meet stringent quality, safety, and compliance requirements.

SEND US A MESSAGE WITH YOUR ENQUIRY

To learn more about our projects and comprehensive EPC solutions, please contact us.