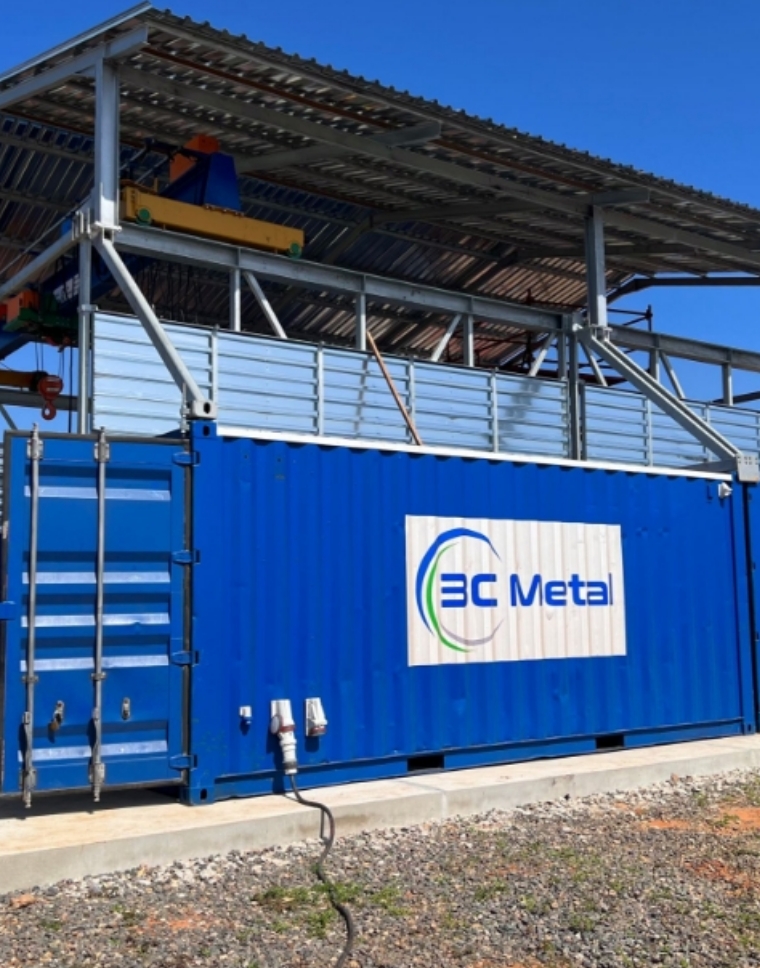

Formed in 2018, Cinco Engineering is a Broad-Based Black Economic Empowerment (BBBEE) joint venture uniting 3C Metal Belmet, Nico’s Engineering, Akram Consulting, and MCM Blasting for local project delivery.

Cinco Engineering was established through the collaboration of these four experienced South African service providers, bringing together a diverse range of technical capabilities. The joint venture combines expertise in engineering, fabrication, consulting, and surface preparation to deliver industrial solutions tailored to local project requirements.

With a focus on efficiency and quality, Cinco Engineering supports infrastructure and energy-related developments across the region. By aligning resources and knowledge, the venture ensures a streamlined approach to project execution while contributing to sustainable growth and development within South Africa’s industrial and economic landscape.

Company Overview

- Location: Cape Town Harbour, South Africa.

- Facility: 4000m², cranes – 3 x 25T; 1 x 20T, 11T, 10T and 5T.

- Specialized services: (As per scope) Fabrication and installation of steel structures as well as industrial high pressure and hydraulic piping. Mechanical fitting, ship repair and maintenance work and management of subcontracted activities.

- Certifications: ISO 9001:2015 (Certified by DNV) | ISO 3834 – 2 (Certified by SAIW) | B-BBEE Level 2.

Capabilities and Services

We deliver integrated fabrication, engineering, and installation services, offering customized solutions for complex projects in the oil, gas, and marine sectors.

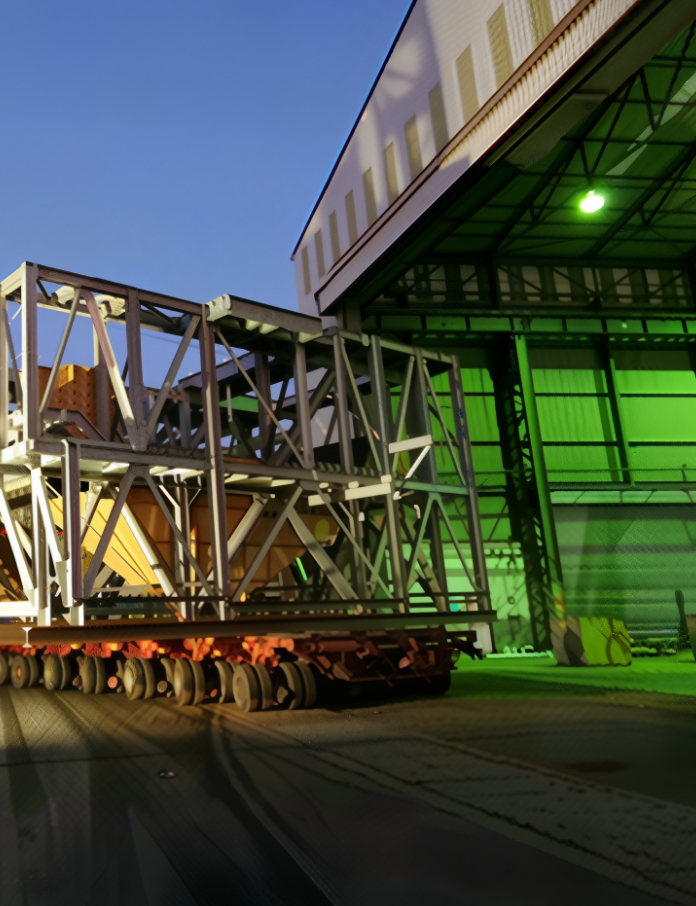

INDUSTRIAL FABRICATION

Fabrication and installation of steel structures as well as industrial high pressure and hydraulic piping.

MECHANICAL FITTING

Installation, alignment, and assembly of mechanical components, systems, and piping in industrial environments.

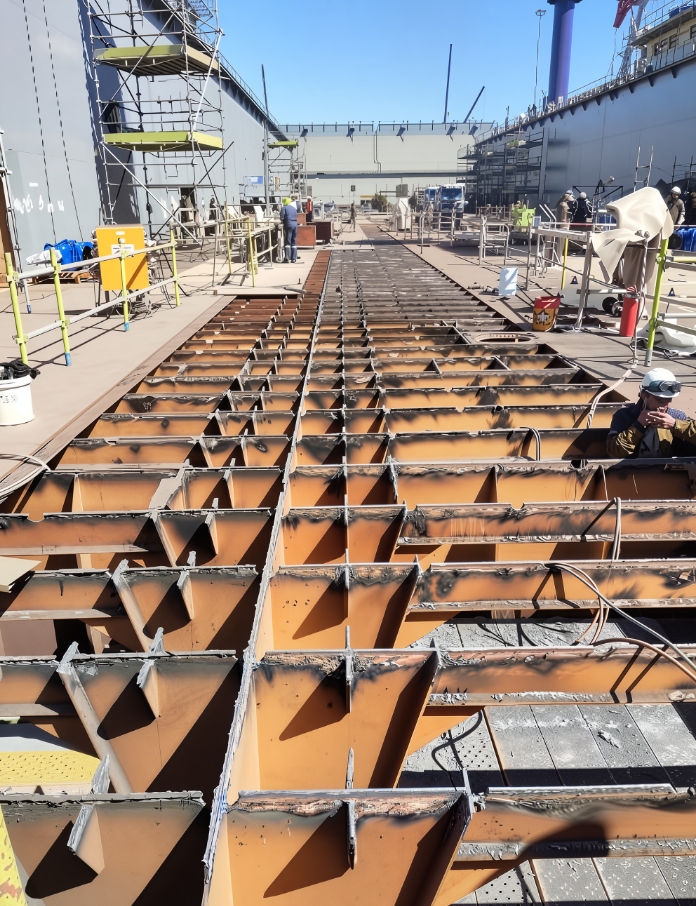

SHIP REPAIR

Inspection, maintenance, and restoration of ship structures, systems, and components to operational standards.

MAINTENANCE WORK

Routine and corrective maintenance of mechanical systems, piping, and structural components to ensure operational efficiency.

MANAGEMENT OF SUBCONTRACTED ACTIVITIES

Coordination, supervision, and quality control of subcontracted tasks to ensure compliance with project requirements.

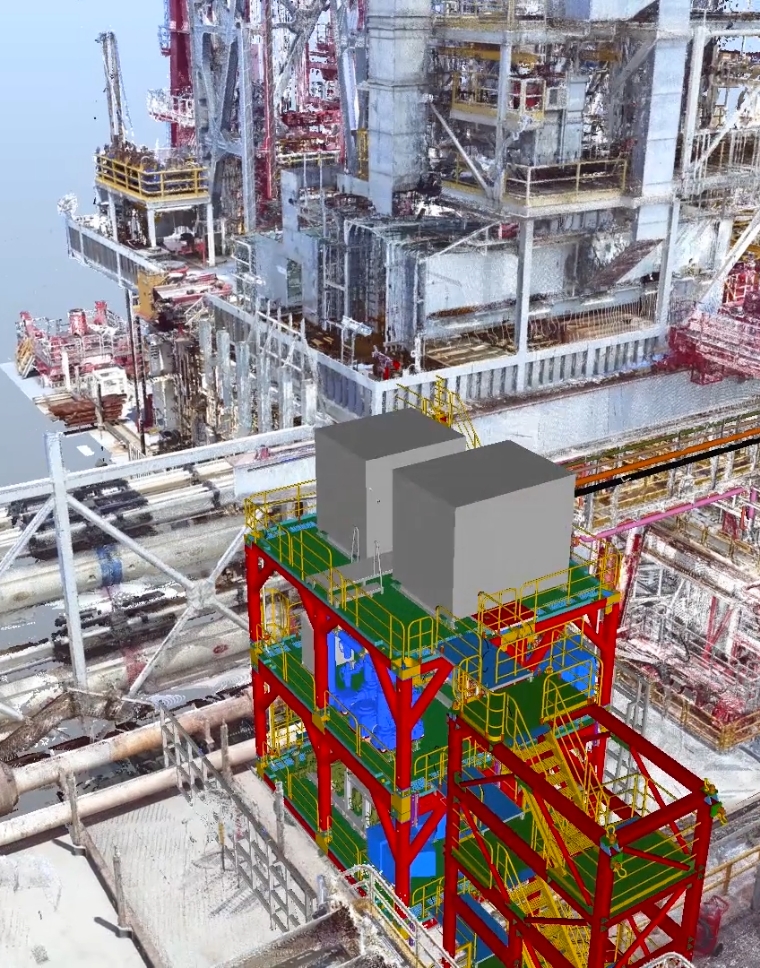

OUR PROJECTS

Explore our diverse portfolio of piping and structural projects, executed with precision through expert welding, NDT, pressure testing, heat and surface treatments, and completed with meticulous installation and inspection services.

OUR CERTIFICATIONS

With globally accredited certifications, we ensure every operation meets rigorous standards of quality, safety, and regulatory compliance.

SEND US A MESSAGE WITH YOUR ENQUIRY

To learn more about our projects and comprehensive EPC solutions, please contact us.