Over the years, 3C Metal France has served as the group’s operational and administrative headquarters, delivering piping and structural work of varying sizes and complexity, supporting engineering solutions for the oil and gas industry and beyond.

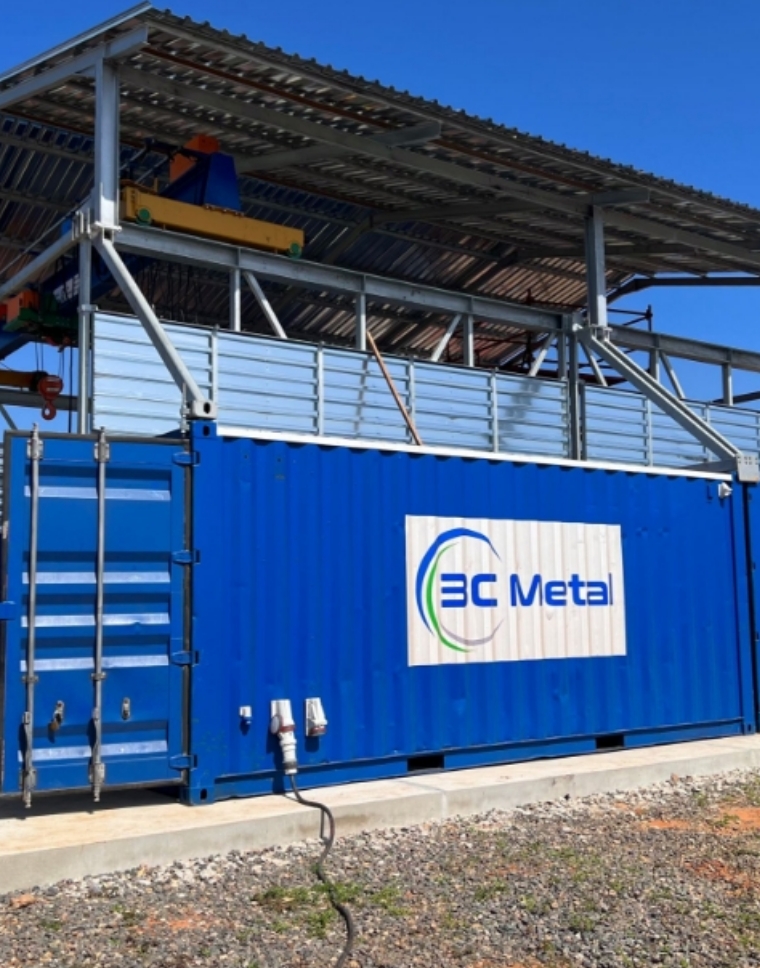

Located in Sauvelade, France, 3C Metal’s facility is equipped to support a wide range of complex fabrication and assembly projects. The site includes expansive covered and open workshop areas, designed for efficient handling of large-scale structural and piping works. With advanced tools and infrastructure, the facility enables high-precision manufacturing tailored to diverse project requirements.

Operations are carried out in strict compliance with internationally recognized quality, safety, and trade standards, reinforcing the company’s commitment to excellence. This robust foundation allows 3C Metal France to consistently deliver reliable, high-quality results across industries, while maintaining strong operational discipline and adherence to regulatory requirements.

Company Overview

- Location: Sauvelade, France

- Facility: 2,000m² covered workshop and 4,000m² open fabrication yard

- Specialized services: EPC Project management and refinery upgrades and shutdowns

- Codes and standards: Quality Certification ISO 9001 | Safety Certification MASE/France CHIMIE (equivalent to ISO 45001) | Authorised Economic Operator Full FR AEOF00166159.

Capabilities and Services

We provide comprehensive fabrication, engineering, and installation services, including tailored solutions for complex oil and gas and industrial projects.

PRESSURE PIPING

High Pressure and Low Pressure piping systems for industrial fluid transport.

HYDRAULIC PIPING

Hydraulic piping systems for high-pressure fluid transmission in industrial, marine, and heavy machinery applications.

POST WELD HEAT TREATMENT (PWHT)

PWHT process reduces residual stresses and enhances material strength, durability, and structural integrity after welding.

HP TESTING

High-pressure testing services up to 30,000 PSI ensure system integrity, safety, and performance under extreme conditions.

STRUCTURAL FABRICATION

Structural fabrication services for building durable steel frameworks in oil and gas, industrial, and infrastructure applications.

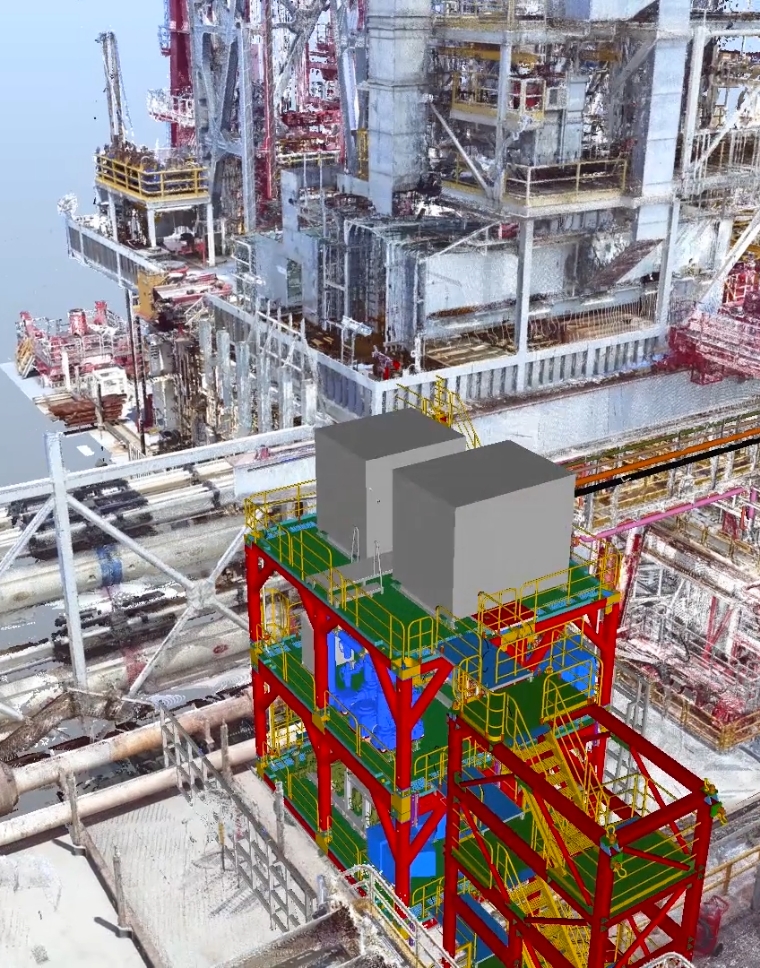

OUR PROJECTS

Explore our diverse portfolio of piping and structural projects, executed with precision through expert welding, NDT, pressure testing, heat and surface treatments, and completed with meticulous installation and inspection services.

OUR CERTIFICATIONS

We are commited to quality, safety, and compliance—ensuring every project meets the highest industry and regulatory standards.

SEND US A MESSAGE WITH YOUR ENQUIRY

To learn more about our projects and comprehensive EPC solutions, please contact us.